Solutions

LXN III

Not just a laser cutting system from coil. In the words of our customers, this extraordinary machine is a real cashflow generator: material savings of over 20%,

optimal management of long products and thin and delicate materials and also reduction to the minimum of manpower.

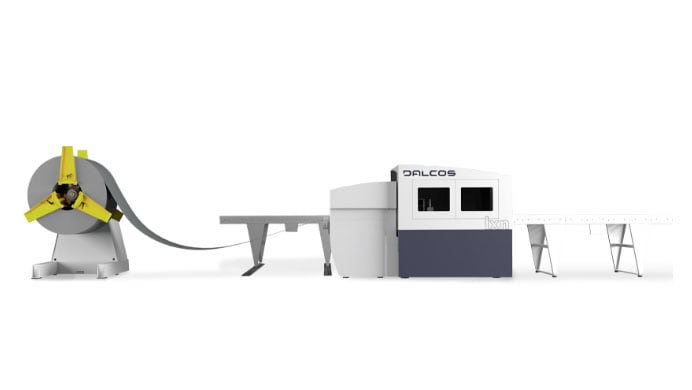

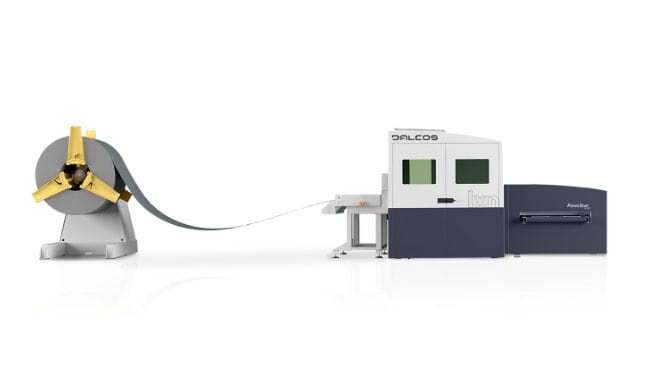

LXN

Simplicity meets state-of-the-art laser cutting technology. High-speed cutting and energy efficiency as well as constant incredibly high precision. Unprecedented production flexibility with the freedom to process either coils or standard size sheets.

Powersort

Automatic sorting and separating system for the laser cutting machines. Exclusive patented technology for suspended laser

cutting that cuts the material without requiring any support.

The best coil-fed laser machines, with vision system.

To guarantee you get the best result, we have developed a range of laser machine models that are suited to the most diverse needs. All our machines are equipped with the exclusive patented vision system, which allows adjustment of the position of the coil and the perfect optimization of the cutting surface!

Extraordinarily precise coil-fed laser cutting machines.

The Laservision vision system offers two main advantages: for the processing of long products, it allows you to reposition the coil with great

precision and to process parts up to 14 metres in length without waste!

The second advantage is that you can use coils of the exact width of the product, making full use of the material: the vision system will

ensure that the cut always adheres exactly to the edge of the material.

The fiber laser source is the most reliable on the market: Dalcos uses components, such as sources and cutting heads, which are produced

by the two main manufacturers, in order to guarantee reliability and utmost in terms of continuous processing!

Dalcos portfolio also includes combined laser-punching systems that guarantee the maximum level of productivity joining the power of punching with the flexibility of laser cutting.

All Dalcos machines are equipped with D-Touch software and they are available with smart automation systems for the discharging and sorting of the processed parts.

LaserVision technology: the patented vision system.

The exclusive Dallan Vision System uses a high-resolution camera that identifies the edges of the panel or coil and the pre-punched holes. The way it works is extremely simple, given that the operation is completely transparent to the operator and the algorithm developed by Dalcos engineers takes care of all the measuring and calibration.